Qualitative criteria

Let’s start with quality requirements. At this stage of process selection, we will skip the business grounds for our actions. We will discuss them later in this article.

- The process must be digital

This is the first and crucial criterion. Digital means that a process is carried out using applications ran on a server or the employee’s workstation. For leading Robotic Process Automation technologies, it does not matter whether the applications are written on request or they are elements of office suites or other popular solutions. It is also not relevant if applications have user interface made available via a browser, customer’s desktop (that is an application installed on a workstation), or a text terminal.

- A possibility to redesign the process

Thanks to that the process can be carried out by a robot. If so far the process has been started from receiving a letter or a call from a customer and launching it has required specific information (for example, a full name, personal identity number, contract number), a simple form (web, Excel, Access, Google Forms and so on) can be prepared to collect the necessary data and transfer it to a robot to carry out a task.

If the process should be finished with sending a letter to a customer, the situation is even easier. The simplest scenario is to generate an appropriate document after filling out a template prepared in the chosen text editor.

- A possibility to describe the process as a set of rules

Automation will be based on implementing those rules in the previously selected RPA tool. It means that we can automate most of transaction processes. Still, even the best RPA solution will not create a new advertising spot or an improved formula of our product for us.

- No expert assessment (for example, analysis of photos or trends)

The criterion is strongly connected to the previous one. It is not the domain of RPA technology but rather of Artificial Intelligence/Machine Learning. However, you need to remember that skillfully designed robotization process will allow combining it with other technologies, such as chatbots, AI/ML, OCR, and many more, in the future.

Quantitative criteria

By following the rules mentioned above, we are able to select processes that can be automated. But these criteria are clearly qualitative, and we do not know yet whether it is worth it to automate those processes. What should be taken into account to determine the potential benefits?

- The number of full-time positions (so-called FTE — a full-time equivalent or a full-time employee) involved in carrying out a process

If we do not know this parameter, we can assess it. We measure the time of a single transaction (for instance, registering and processing a request in the system), and we multiple it by the average number of requests per month. After dividing the result by the average number of working days in a year, we will have the average monthly cost of carrying out a process expressed in FTE.

- The repeatability of process

The more often a process is carried out, the bigger are the benefits from its automation.

- The complexity of process

It has an impact on costs related to the implementation and later maintenance. Depending on the methodology adopted in the company, different criteria can be specified: duration of a single sequence, the number of decisions made during the process, the number of processing paths (related to the number of decisions,) the number of applications that should be used by a robot, the number of clicks or any other actions in systems, etc.

- The stability of the process and applications supporting its completion

Frequent changes in the process or supporting applications, will force continuous changes of robots. This means additional costs necessary to maintain the automated process.

The first two parameters will enable us to assess the potential benefits. It is worth remembering that timesaving, which is easy to translate into financial benefits of organizations, does not have to be the only profit from automation.

Process robotization can bring other, sometimes difficult to measure benefits such as:

- Improved work satisfaction and reduced employee rotation (which means lower costs of HR support)

- Improved quality of the carried-out process thanks to fewer mistakes

- Reduced time of customer service

- Improved compliance and the possibility of tracing carried out tasks

Process selection

After creating a list of processes with metrics based on the above-mentioned criteria, we can proceed to the aware selection of the first processes to automate.

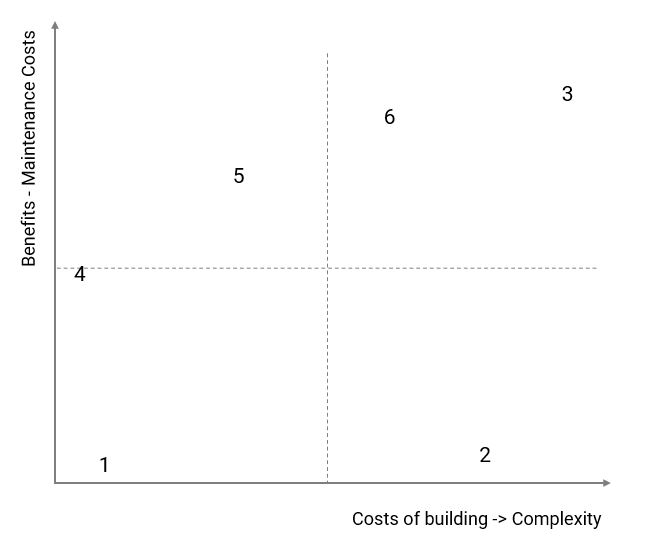

Figure – The selection of RPA processes. Author’s compilation.

On the coordinate system (x-axis — costs of building that derive from the process complexity; y-axis — benefits from the automation after considering the costs, mainly maintenance and licensing), we put the identifiers of our processes, according to previously collected metrics.

What conclusions can we draw based on the graph?

First of all, we should not build robots for processes #1 and #2. The assessed benefits in both cases are low, and it can result in a lack of sponsor’s interest in further stages of process robotization. Additionally, the process #2 brings a significant risk of implementation failure because of its high complexity and, consequently, difficult implementation.

In our case, it is best to start the adventure of business processes robotization from building a robot for the process #4. This choice will allow us to prove that the robotization initiative has a business case. The process is relatively simple so the risk associated with robot implementation should be lower, but the return on investment in building a robot could be higher.

Other processes which are worth taking into account, are #5, #6 and #3 respectively. The benefits of implementing them are similar, and their increasing complexity should be compensated by the growing experience of the team that builds robots.

Summary

After a first few months of operation of a robotization program, we recommend reviewing the estimates and taking another overview of processes, especially regarding the estimated costs of building robots. The benefits from the implementation should be already visible, including the aforementioned competence development in the team responsible for Robotic Process Automation that will result in reduced implementation time when other business processes are robotized. The benefits of the possible future use of already implemented modules and paving the way will also be noticeable, especially for the most unmanageable applications in our company.

Soon, you will find on our blog next articles about RPA and the way it can support digital transformation in an organization. You are welcome to read it!

- RPA Consultant

-

A manager with over 15 years of experience in software and technology consulting. A graduate of the Warsaw University of Technology and the Warsaw School of Economics experienced in managing big teams (over 50 FTE) in international programs and projects. He has cooperated with clients from the financial, manufacturing, and telecommunication industries in Europe and the Middle East. At Craftware, he is responsible for consulting and development of RPA services.